Are you looking for a way to efficiently prepare solvent-based products such as: OEM paint, car refinish, enamel, high performance coatings, coil coatings, marine paint, and more? If so, then Inkmaker has the solution for you!

Our user-friendly systems are all customised to clients’ requirements and specifically designed to not only reduce production costs and time but to also ensure safety and compliance with regulations in hazardous environments.

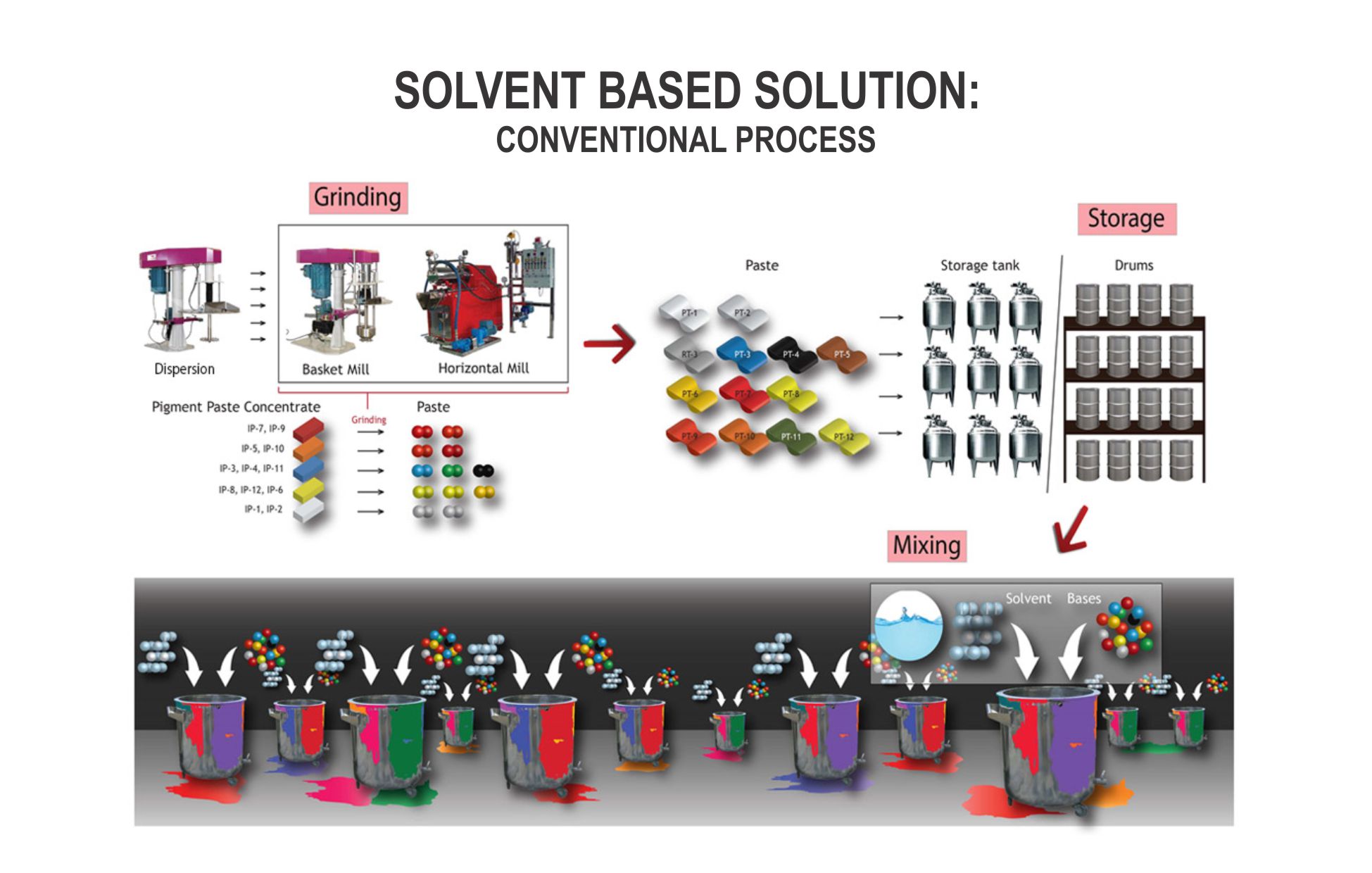

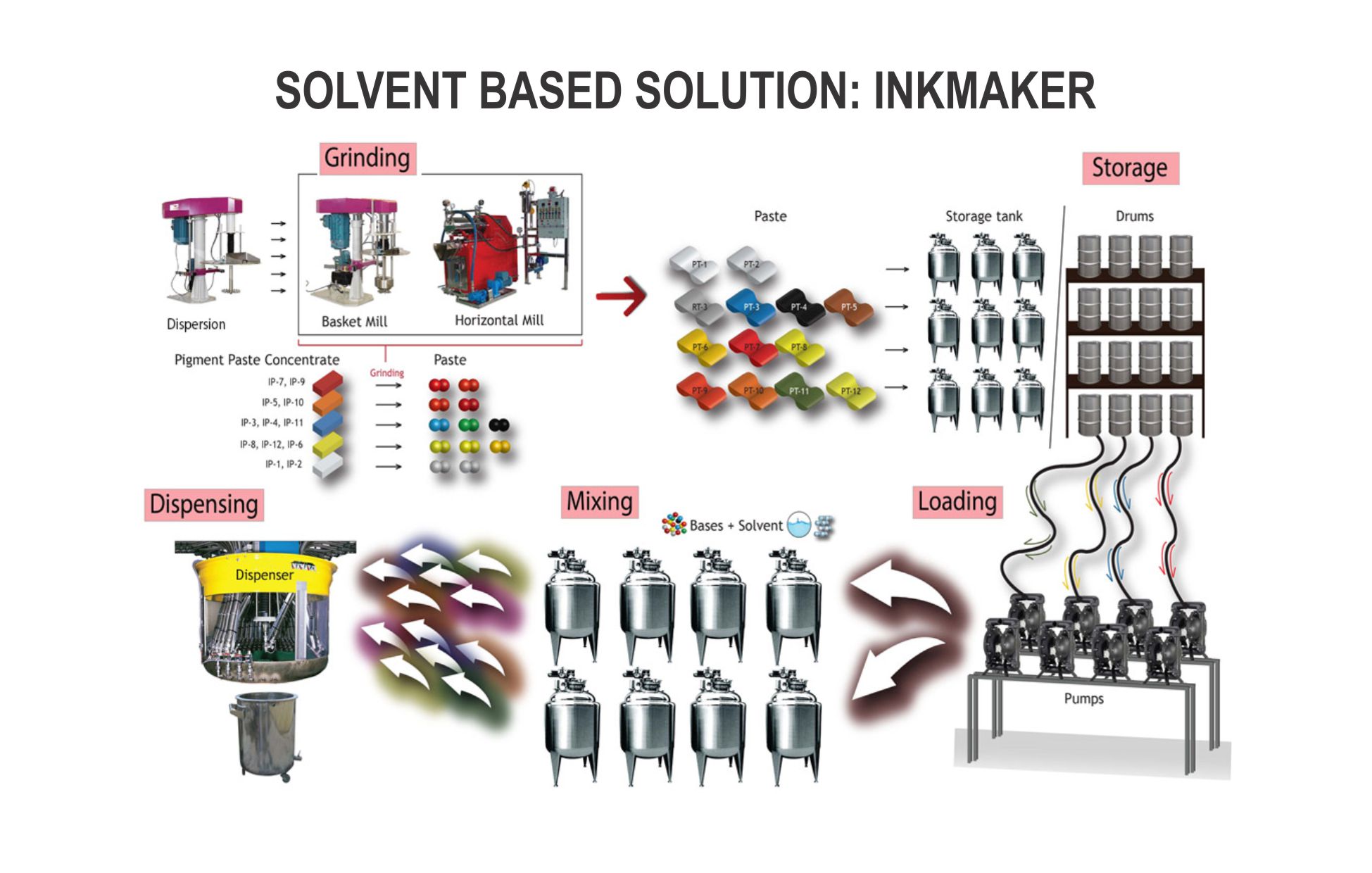

With electronic scales controlling the product weight during dispensing and custom-designed piping systems connecting components to dispensing heads, our solutions are both precise and efficient. Whether you need to store products in drums or storage tanks of different dimensions, which can also be equipped with built-in mixers, our custom designed piping system makes the whole process seamless and easy to manage. Additionally, the dedicated pumps that deliver products directly to the dispensing head, can also refill storage tanks with fresh products through custom-built “loading stations”, providing a versatile solution for various production needs.

The Easypaint software-controlled system also archives all formulas in a PC, controls operations, including those relative to storage tanks reloading, monitors stock and tracks batches, ensuring efficient management of all processes.

For a broad range of colours and batch sizes between 400 to 2,000L, our EASYPAINT IN-BATCH solution is the perfect fit. And for smaller batches below 400L, our EASYPAINT IN-CAN solution is ideal.

Ready to transform your solvent-based production?

Discover how EASYPAINT can streamline your processes, ensure compliance, and optimise efficiency for every batch size.

Contact us today to learn more about EASYPAINT or other innovative Inkmaker solutions!

In-Batch Tinting

In-Can Tinting