Are you looking for a solution to ensure quality and consistency in your production process? The Inkmaker Automatic Additives Dosing System is the latest innovation in the industry, designed to revolutionise the way you add additives to your production process, it is the answer to one of the industry’s most crucial and delicate production processes.

No more human errors or inconsistencies — our software-controlled solution ensures accurate and precise dosing every time.

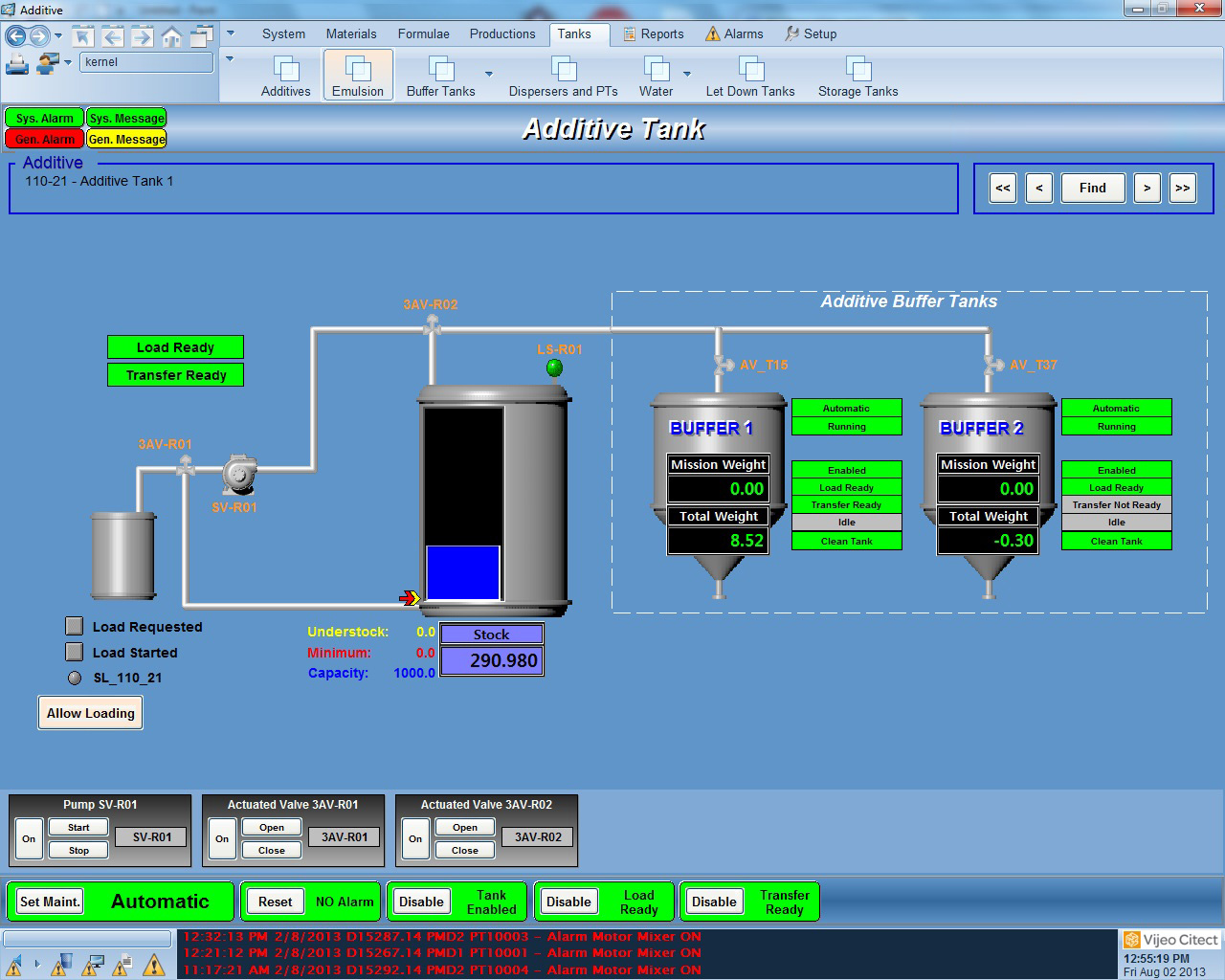

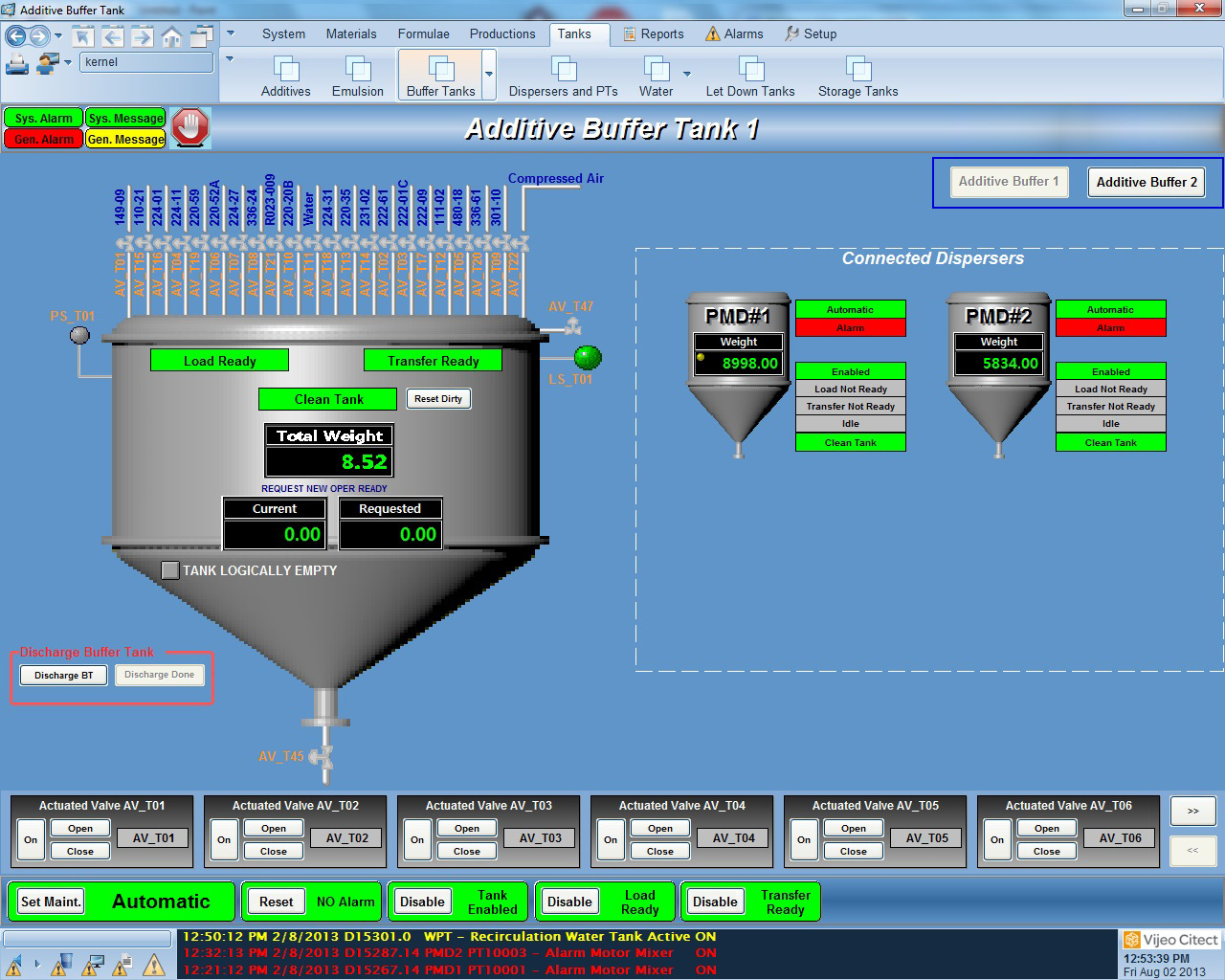

We understand that every production process is unique, which is why our system is tailored to meet your specific needs. Whether you're working with small or large tanks, our system can be customised to fit seamlessly into your operation. Additives can be stored in dedicated containers and, when needed, pumped into stainless steel hoppers mounted on electronic scales. Once the precise amount of each additive has been measured, they are automatically transferred through a custom-designed distribution system directly to the process tanks without any human intervention, eliminating potential human errors.

With real-time monitoring and dedicated pumps, for handling individual additives, our system guarantees that correct sequences are followed and that only the correct quantity of additives is used. Additionally, our software controlled automated cleaning, of the additives’ dispensing hopper, avoids any possible cross-contamination issues.

The Inkmaker Automatic Additives Dosing System guarantees cutting-edge quality and efficiency. Upgrade your production process to a new level of control and consistency and experience the difference.

Struggling with additive inconsistencies?

Discover how the Inkmaker Automatic Additives Dosing System ensures precision, quality, and efficiency in your production process.

Contact us today to learn more about this innovative solution or other Inkmaker systems tailored to your needs!