Navigation Menu...

STEP BY STEP OPERATION PROCEDURES

Inkmaker automatic, software controlled additives dosing system is the answer to one of the most crucial and delicate production’s process: additives dosing.

Our automatic additives dosing system ensures the quality and consistency of the final products by eliminating dangerous and costly mistakes.

All our dispensing solutions are tailor made according to each customer's specific requirements.

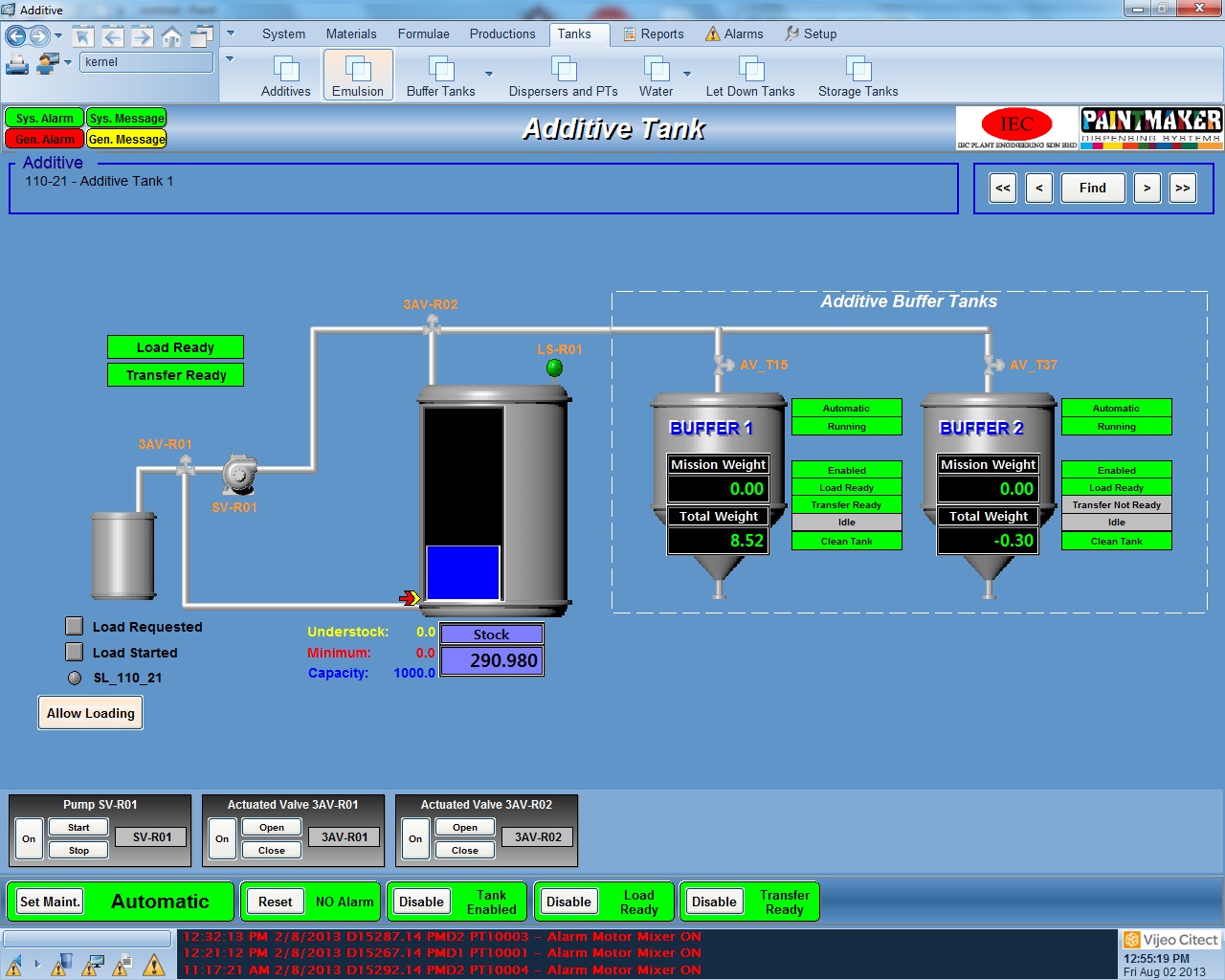

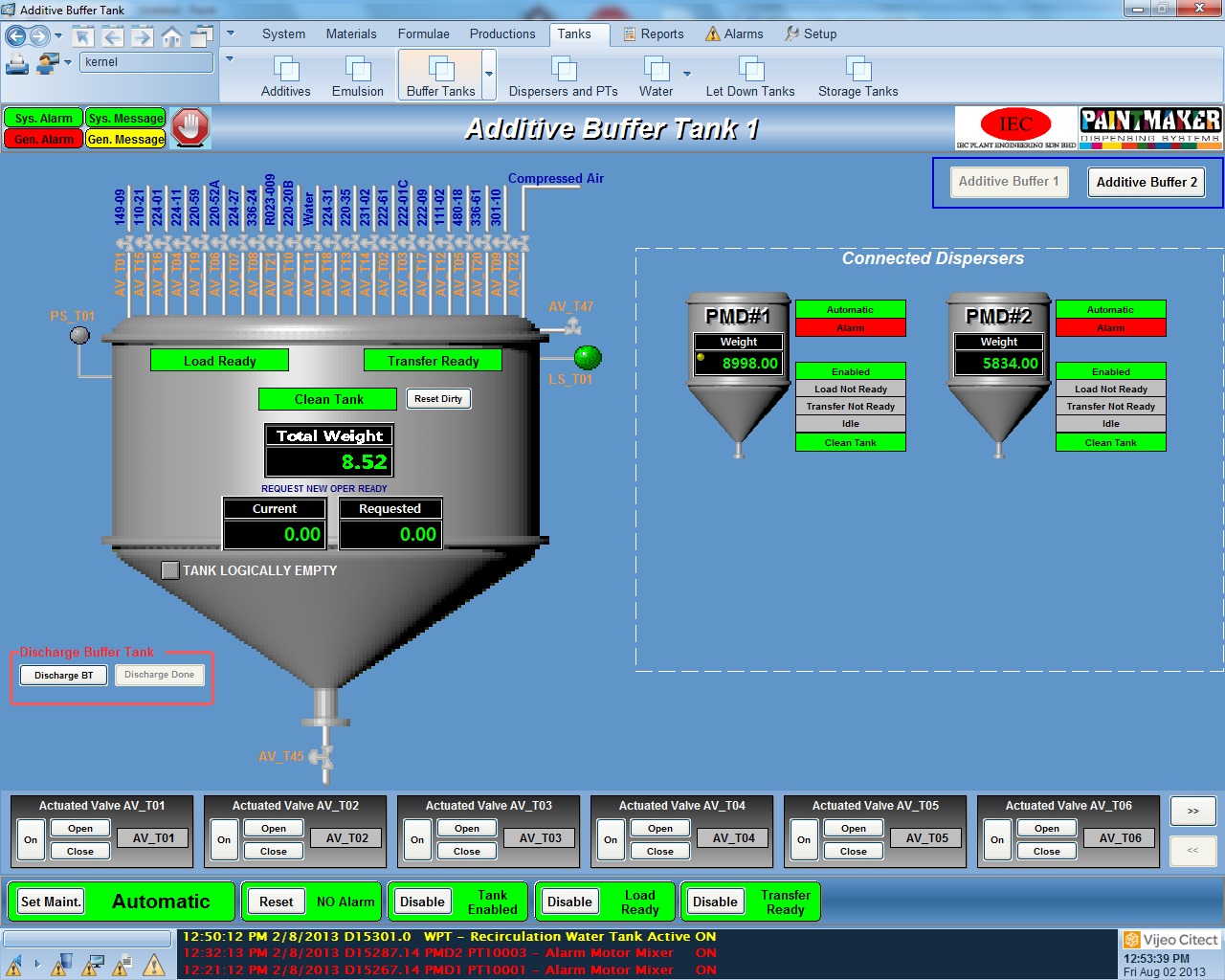

Additives can be stored in dedicated containers and, whenever necessary, pumped into stainless steel hoppers mounted on electronic scales.

Once the exact quantity of each additive has been measured, they are transferred through a custom designed distribution system, directly to the process tanks.

Using our automatic additives’ dosing systems you can: